Equipment Repair Management

Equipment repair management is essential for ensuring the longevity and optimal performance of assets within various industries. Effective management of repair processes not only reduces operational downtime but also enhances asset management by providing a clear framework for equipment maintenance tracking and repair order management.

With the increasing reliance on machinery and equipment, organizations must adopt a comprehensive maintenance management system that integrates equipment repair scheduling and repair optimization strategies. This approach ensures that all repairs are efficiently managed, ultimately contributing to improved productivity and cost-effectiveness.

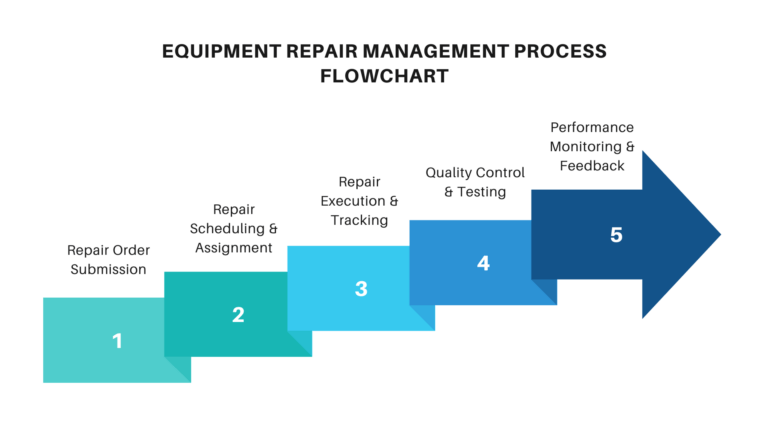

How Equipment Repair Management Works

- Centralized Repair Order Management

- A maintenance management system centralizes all repair requests, ensuring that all orders are logged and tracked for efficient handling.

- Equipment Maintenance Tracking

- Implementing asset management software allows organizations to track maintenance history, ensuring that all repairs are documented and easily accessible.

- Automated Repair Scheduling

- Automated scheduling tools facilitate timely repairs by alerting maintenance teams when equipment is due for service based on predefined criteria.

- Performance Monitoring

- Regular monitoring of equipment performance helps identify potential issues before they escalate into costly repairs, enhancing equipment repair optimization.

- Data-Driven Insights

- Utilizing data analytics can help organizations identify trends in equipment failures and repair needs, enabling informed decision-making for future maintenance strategies.

Relevance to Businesses

Effective equipment repair management is critical for several reasons:

- Minimized Downtime: A structured approach to repair management ensures that equipment is quickly serviced, reducing the impact on productivity.

- Cost Control: By optimizing repair processes and schedules, organizations can significantly reduce maintenance costs associated with emergency repairs.

- Improved Asset Lifespan: Regular maintenance and timely repairs extend the life of equipment, enhancing overall asset management.

- Regulatory Compliance: Adhering to maintenance schedules and documenting repairs help businesses comply with industry regulations and standards.

Key Benefits of Equipment Repair Management

- Enhanced Asset Reliability: Consistent repair management ensures that equipment remains in good working condition, preventing unexpected breakdowns.

- Operational Efficiency: Streamlined repair processes minimize disruptions, allowing staff to focus on core business activities.

- Cost Savings: Reducing emergency repairs and optimizing maintenance schedules leads to significant cost reductions.

- Informed Decision Making: Access to data-driven insights enables organizations to make informed choices regarding repairs and replacements.

- Improved Compliance: Proper documentation of repair activities assists in meeting regulatory requirements and industry standards.

Top 10 Statistics for Equipment Repair Management

- 62% of organizations report that implementing a maintenance management system has reduced their equipment downtime by over 30%.

- Companies that utilize asset management software can reduce maintenance costs by 20% on average.

- 60% of maintenance teams that automate their scheduling see a significant increase in productivity within the first year.

- Effective equipment maintenance can increase the lifespan of assets by up to 40%.

- Organizations using computerized maintenance management systems (CMMS) experience a 15% increase in compliance with industry standards.

- Over 80% of equipment failures are due to poor maintenance practices, highlighting the need for robust repair management strategies.

- 97% of companies that implement a proactive maintenance strategy report a decrease in equipment repair costs.

- Companies that adopt mobile maintenance management tools can reduce repair response times by 50%.

- More than 70% of organizations have seen an increase in customer satisfaction after implementing effective repair management processes.

- Maintenance tasks that are documented properly can improve team collaboration and information sharing by up to 60%.

Equipment repair management is crucial for optimizing asset performance and ensuring operational efficiency within organizations. By leveraging advanced maintenance management systems and adopting best practices for repair scheduling and tracking, businesses can achieve significant improvements in equipment reliability and overall productivity.

Our trusted customers