Equipment Calibration Software

Equipment calibration software is a tool that automates the tracking, scheduling, and documentation of equipment calibrations, ensuring tools and machinery operate within required standards. Used across industries like healthcare, manufacturing, and field services, it ensures that assets such as medical devices, pressure gauges, or industrial tools are accurate and meet regulatory standards.

The software also integrates with asset and inventory management software, providing detailed insights into calibration history, compliance requirements, and future maintenance schedules.

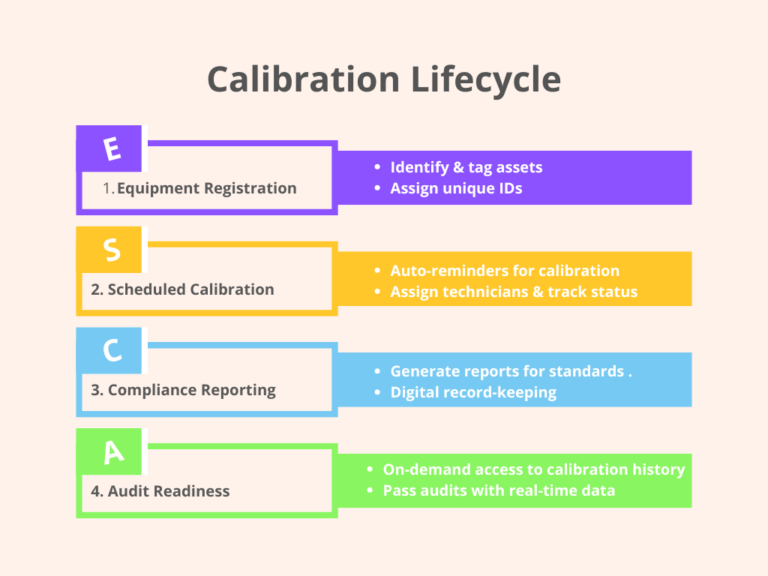

How Equipment Calibration Software Works

- Asset Registration and Tagging:

- Equipment is registered in the system, often using RFID tags, barcodes, or serial numbers for tracking.

- Automated Scheduling and Alerts:

- The system generates calibration schedules based on the asset’s usage patterns or regulatory requirements and sends automated reminders.

- Data Entry and Real-Time Documentation:

- Calibration data, including measurements, dates, and personnel involved, is recorded instantly through the software.

- Compliance Reporting and Audits:

- The software maintains detailed logs of calibration activities to facilitate regulatory audits and compliance reviews.

- Integration with Inventory Management Systems:

- Integrating with inventory management systems ensures that equipment is tracked throughout its lifecycle, from calibration to disposal.

This process ensures that equipment maintains peak performance, reduces unexpected downtime, and avoids non-compliance penalties.

Relevance to Industries

Calibration is critical in industries where precision and safety are paramount, such as healthcare, manufacturing, and telecommunications. Here’s how equipment calibration software enhances operations across sectors:

- Healthcare: Medical equipment like ventilators or infusion pumps require precise calibration to ensure patient safety and comply with regulatory bodies like the FDA.

- Manufacturing: Industrial tools such as pressure gauges or torque wrenches must meet precise standards to avoid defective production.

- Telecommunications: Calibration ensures signal quality and consistency across networking equipment, reducing service interruptions.

- Field Services: Companies managing remote or field assets use calibration management tools to streamline their operations and ensure all equipment is compliant, even in different locations.

Key Benefits of Equipment Calibration Software

- Improved Compliance: Tracks calibration history to meet regulatory standards like ISO 17025 and ensure smooth audits.

- Reduced Downtime: Proactive scheduling prevents unexpected breakdowns by keeping assets calibrated and ready for use.

- Enhanced Accuracy: Ensures that equipment operates within expected performance levels to avoid faulty results or defects.

- Cost Efficiency: Avoids unnecessary re-calibration and extends the lifespan of equipment.

- Better Documentation: Provides detailed calibration logs for easy audit trails and transparency.

Top 10 Statistics for Equipment Calibration Software

- 30-40% reduction in non-compliance risks with automated calibration software.

- 50% decrease in calibration-related downtime reported by industries using calibration management systems.

- 75% of manufacturers say that calibration management is essential for maintaining product quality.

- Medical facilities that automate calibration see an average of 30% fewer equipment-related incidents.

- $10 billion global market size forecast for calibration management software by 2030.

- 90% improvement in audit readiness when calibration systems are integrated with asset management tools.

- 25% increase in equipment lifespan when regular calibration schedules are maintained.

- Two-thirds of healthcare providers report fewer service disruptions with calibration tracking systems.

- 60% of companies plan to adopt IoT-enabled calibration solutions by 2027.

- 20% reduction in operational costs due to better calibration management.

Equipment calibration software plays a vital role in industries that demand high precision and compliance. By automating calibration schedules, reducing downtime, and maintaining regulatory standards, these tools ensure that organizations can operate efficiently without compromising on quality. Integrating with asset management systems further enhances operational transparency, helping businesses meet compliance requirements while optimizing asset performance.

Our trusted customers