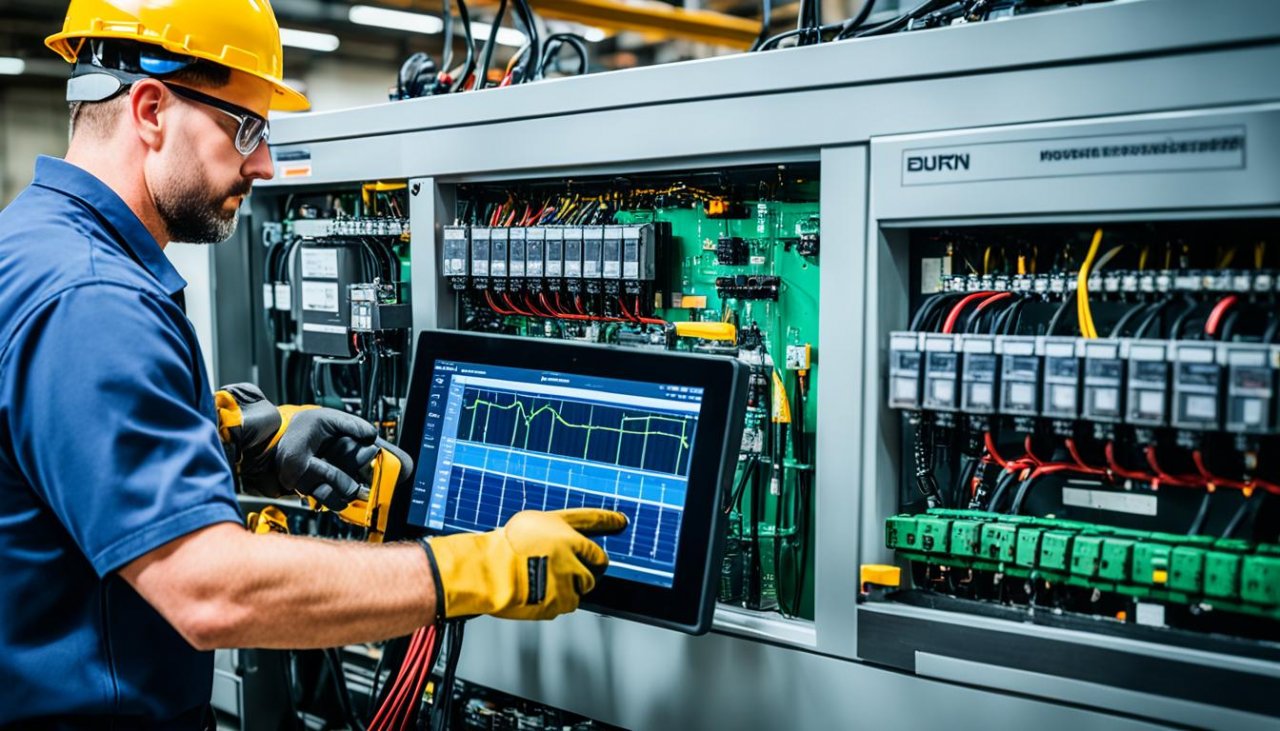

Imagine being the owner of a busy manufacturing plant. Your work depends on machines to run the production line. One day, you hear a strange sound from a machine.

This sound worries you as a breakdown could halt your production. You call in the maintenance team. They check the machine, find the problem, and fix it. Your production remains on track thanks to their quick work.

Now, think about predicting that the machine would fail before it did. This is where predictive maintenance, or PdM, is key. It uses technology and data to foresee equipment issues.

PdM faces some big challenges, like its startup costs and needing a lot of data. Plus, some workers might not like changing how they work. But, it’s worth it. It cuts down on repair costs, makes equipment more reliable, and keeps customers happy.

This article looks at how predictive maintenance helps with field service challenges. We’ll discuss the obstacles of starting PdM in service work, its perks, and how to make it work well.

Key Takeaways:

- Predictive maintenance helps businesses anticipate and prevent equipment failures.

- Implementing PdM comes with challenges like high costs and employee resistance.

- However, overcoming these challenges leads to reduced maintenance costs and improved equipment reliability.

- Successful PdM implementation requires careful planning, employee involvement, and continuous improvement.

- Predictive maintenance provides significant competitive advantages in field service management.

Challenges of Implementing Predictive Maintenance in Field Service

Starting a predictive maintenance program can be hard for companies. They face several hurdles that must be solved for it to work well. Some obstacles include:

High Initial Costs

Setting up predictive maintenance is costly. You need to buy the right tools and software. These help watch over machines and catch problems before they happen.

Managing and Analyzing Large Amounts of Data

It needs lots of data crunching to make predictive maintenance work. But handling and making sense of all this info is not easy. You must have strong data systems and tools for the job.

Resistance to Change

Some workers might not like switching to this new method. To get everyone on board, you’ll need good strategies and training. This helps staff see why it’s better and how it helps them.

Privacy and Security Concerns

Keeping data safe is a big worry, too. It’s about making sure machine data stays private and secure. This means using top security and following rules to win people’s trust.

Ongoing improvements and fitting with new needs is another challenge. Regular checks and tweaks are key. This way, you keep making the most of your predictive maintenance program’s benefits.

By tackling these issues, companies can launch predictive maintenance well. This opens up a world of good things for their field service work.

Benefits of Predictive Maintenance in Field Service

Implementing predictive maintenance in field service faces some hurdles. Yet, it brings many benefits. Using technologies like IoT sensors and predictive analytics helps businesses. They can spot possible equipment failures early and plan maintenance. This lessens equipment downtime, cuts maintenance costs, and makes customers happier.

By using predictive maintenance, businesses can make their maintenance plans better. They can extend the life of their equipment and run more smoothly. With help from IoT sensor data, companies see how their equipment is doing. Then, they can decide the best times for maintenance.

Predictive maintenance lets businesses forecast equipment failures. This way, they can act before something breaks down. This helps avoid sudden failures and the costs that come with fixing them. Also, it lets companies use their equipment for longer. They won’t have to buy new items as often, saving them money.

Predictive maintenance also makes customers happier. When businesses do maintenance before something breaks, service doesn’t stop. So, customers don’t have to wait for fixes. Their service runs smoothly without interruptions.

To sum up, predictive maintenance is great for field service businesses. With IoT and predictive analytics, they cut downtime, spend less on maintenance, run better, make their equipment last longer, and keep customers satisfied.

Strategies for Successful Predictive Maintenance Implementation

To make predictive maintenance work well, you must have a solid plan. This approach will bring the most benefits in managing services. These strategies help businesses smoothly add predictive maintenance:

1. Define Goals and Objectives

Start with clear goals in mind. Know where and how predictive maintenance will make things better in your operations. It can boost efficiency and save money in your services.

2. Select the Right Technology and Tools

Pick the best tech and tools that fit your needs. Look at how data is collected and analyzed. Think about how they work with things you already use. New tech, like IoT sensors and cloud platforms, can make your maintenance plans smarter.

3. Involve Employees

Get your team on board by training them. Make sure they know the good things about predictive maintenance. Like lower downtime, better machine use, and safety. It’s important they see the benefits and feel involved. This helps smooth out any bumps as you make changes.

4. Prioritize Data Management and Security

It’s key to handle data well. Set up clear processes for the data from sensors and more. Keep this data safe. Always keep your data clean and up to date to get the best results from your predictive maintenance.

5. Continuous Improvement and Monitoring

Keep checking on how well predictive maintenance is working for you. Look at things like how often your equipment is up, costs, and what customers say. Use what you learn to do better. This will help you fine-tune how you use predictive maintenance in your services.

Follow these guidelines to add predictive maintenance successfully. Doing so can make your equipment work better, cut costs, and lift your business’s performance.

Conclusion

Predictive maintenance is essential for tackling field service issues efficiently. It helps businesses improve how they manage services in the field.

Although it requires a big first step, predictive maintenance is a chance for companies to work smarter, save money, and make customers happier. They can use advanced tech to spot potential problems early. This lets them fix things before they break and keep their machines running smoothly.

It’s important to get employees on board and give them the right training when starting predictive maintenance. Showing the team the benefits can help them welcome the change. This ensures that everyone works together smoothly.

But the work doesn’t stop there. To keep predictive maintenance running well, companies need to always be getting better. They should regularly check how well it’s doing and then tweak their plans. This way, they keep getting better at what they do.

See how FieldAx can transform your Field Operations.

Try it today! Book Demo

You are one click away from your customized FieldAx Demo!

FAQ

What is predictive maintenance?

Predictive maintenance predicts when a machine might need repair. It uses high-tech like IoT sensors. These tools help by warning about issues. Then, maintenance can be done before the problem gets worse.

What are the challenges of implementing predictive maintenance in field service?

Setting up predictive maintenance can be hard. It requires a lot at the start. Data must be managed well. This change might not be welcomed by all. Keeping data safe is also key but this can be tricky.

What are the benefits of predictive maintenance in field service?

Using predictive maintenance has many perks. It cuts equipment downtime and costs. Customers are happier when things run smoothly. This method also makes sure machines last longer. It boosts how well operations take place.

What are the strategies for successful predictive maintenance implementation?

To make this work, start by setting clear goals. Choose the best tech for the job. Make sure your team is on board and trained. Handling data right is crucial. Always aim to get better and watch how the plan is going.

Author Bio

Co-Founder & CMO at Merfantz Technologies Pvt Ltd | Marketing Manager for FieldAx Field Service Software | Salesforce All-Star Ranger and Community Contributor | Salesforce Content Creation for Knowledge Sharing